|

Weekends like this challenge our Core Beliefs. I can firmly state that Bridgewater Dairy agree's with the following statement.

In Balancing Life: God should come first, Family second, and work third. The challenge is how we balance all three parts, and because all three are important, it is up to the individual to figure out that balance. As many may have observed, we harvested over 1400 acres of Alfalfa Haylage and planted over 1000 acres of corn and soybeans, in the last 6 days. Some might say 'we shouldn't have worked Sunday'. No, we haven't taken our Core Beliefs to this level, but I can say we make every effort to minimize the need to work Sunday's and encourage our employee's lead balanced lives. So how does all this play out in a spring like 2010? This year much like last year, we have been faced with the fewest days to plant and harvest our spring crops in our history. This year we planted as many of our acres as possible in 7 days. Often this day consists of an 18 hour day ( 6am to midnight), but occasionally when faced with a significant rain event, we will run a 24 hour in order to get as much planted as possible. Of these seven days, one and a half of them were Sunday's and one of those Sunday's, Memorial day weekend became a 24 hour day for both the planting and the harvest crew. With rain in the forecast all day Monday, and then all week as well it was a decision that had to be made. If we couldn't get a complete harvest of our Alfalfa, or plant as much corn as possible we may run out of food for our animals before the next harvest. Behind the Balance of Work and Life are many difficult decisions, we must use the information available to make the best decisions possible for God, our Employee's families, and our Animals. Drovers published an article on recent animal abuse video's. "Abuse does not represent dairy industry" We encourage you to review and consider this article.

Bridgewater Dairy is in the process of reviewing and updating our Standard Operating Proceedures and animal handling training to ensure the highest animal care standards for our animals. Bridgewater Dairy is also interviewing individuals on farm to discover any potential problem area's with regard to safety and welfare of both animals and people. Well, we aren't completely excited about the soil conditions, but at some point we just had to go for it. Yesterday, afternoon the corn planter began moving again. It had been almost exactly 5 weeks since the planter's wheels had turned and as long as the weather forecast doesn't change much we might finally finish all out planting. Yea!!

Well, another rain delay in the works. If you live in our vicinity, you are well aware of the downpour we had Friday night. Everything seems to be stacking up on us, we have corn and soybeans to plant, Alfalfa to harvest, and would love to run our pivots a little. We have hardly even had time to mow all of our lawns. What a year! (By the way, our rain totals are online at Wunderground.com under the Personal Weather Station info)

This year we decided to purchase a some Alfalfa from Bruce Moody (Moody and Crew) in Fremont, Indiana and Sand Creek Farm near Adrian, Michigan. Moody and Crew mowed some Alfalfa and were getting ready to chop Friday in an attempt to beat the rain. Well, the rain hit early and the 40% chance of 0.5 inch rapidly turned into 3.5 inches. So we will have to wait for the sun to dry this alfalfa out, before we can finish it. If all goes well, and the fields are dry enough to handle the equipment we will start mowing Alfalfa near Adrian, Michigan on Monday. If we have a good week to get the fields dry, we might be able to start planting by Friday, but that is a really BIG "if." Luckily, it appears NOAA has taken the rain out of the forecast for Friday. It might just be a working Memorial Day Weekend, but lets hope we still all get to enjoy part of the weekend. Especially since it appears there might be a few high school graduations for our employee's to attend. And Congrats to the Seniors that are Graduating this year! The Columbus Dispatch published this article about how Agriculture is changing. 'Green' Dreams Farm Fresh Fuel. Our Kudos go to the Columbus Dispatch on a very informative article. Don't miss the Video at the bottom of the article.

It appears we are working all the bugs out of our system, and learning more everyday. Well, maybe we are still a little confused, but in the meantime we are holding some of the highest electric output levels we have seen.

As I checked into the generator's all weekend, I noticed we were producing about 320 KWH for each generator, or 620 KWH. I decided to check in this evening, and was pleasantly surprised to see we are at about 367 on each generator, that's nearly 740 KWH. Not exactly sure what we did to get this high this evening, but we are happy to sell it to the electric coop. From time to time things just seem to happen to us. Well, maybe not so odd. Within the last week someone decided to do donuts in one of our fields. Most likely a teenager showing off, but our employee's who now have to level the tracks out aren't laughing about it. So now the question is do we report it to the local authorities, or just let it slide? This behavior is not appreciated by any farmer in the area and definitely not us. We all work hard, pay for fuel, and equipment to get the fields ready to plant. Its likely we will increase our surveillance, ask a few neighbors, and consider reporting this event.

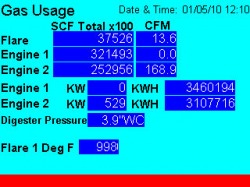

About 4 months ago we installed a Hydrogen Sulfide (H2S) seperation system on our digester. The benefit from this is really multi-faceted, less H2S in our generators which will extend engine life, allow us to use cheaper oils to keep the engines clean, and potentially extend the oil change intervals. Yeah, yeah I know exciting stuff. The system is basically a air injector, that measures flow rate, and adjusts the amount of air injected into the system. Pretty simply, well at least thats what I thought until I saw what the system cost. We were told not to expect to see a change for about 2 months, and to our surprise we saw nothing. GHD, our digester company came out and reviewed the system and discovered a setting in the system was set incorrectly. They adjusted it and this week we have discovered some things that seem to imply that it is working great. One of the negatives of the H2S system is that it can create some bacterial growth that tends to cling to the screens and therefore eventually plug gas flow. This week everything seemed to running just perfect with the digester until we realized the emergency relief valve at the far end of the digester was opened, this valve is only supposed to open when the pressure gets above 8 inches of Water Column (WC). The odd thing is the digital gas pressure guage was only showing around 2" WC. It was time to do some research on what was going on. We were totally confused. Frank eventually came up with an idea. Just above the digester in the pipeline to the gas room is a flame arrestor, it has a radiator-like screen that prevents the very rare occasion that a spark might wander through over 100 foot of pipeline and ignite the entire digester. Maybe this screen was growing bacteria due to the H2S system and confounding pressure guage. He pulled the screen out cleaned it and sure enough we suddenly had over 8" WC in the digester. Now, our only problem is that the gas heat exchanger for genset 1 is plugged, and we are waiting for Wagner-Mienert to come clean it. Once this is completed we strongly believe we will be running both gensets. Something to note. The flare is only supposed to release gas if the gas pressure is above 4"WC. Now, on the above picture notice the digester pressure is only at 3.9" WC. But the flare is processing about 13.6 CFM of gas at a temperature of 998 degrees F. The likely cause is that the flame arrestor needs cleaned. The result of all this: The H2S system appears to be working, and we clearly have enough gas to run both generators.

Also the KWH numbers associated with each generator. The KW numbers indicate current electrical production, and KWH is total KWH produced be each generator since we started operation over a year and a half ago. Keep an eye out, hopefully I'll be posting our success in a few weeks. But, the digester is a lot like a cows stomach we never really know whats going on in there. |

AuthorThis Blog will be Updated by a member of the management team. Archives

January 2011

Categories

All

|

|

Mailing Address:

14587 County Road 8 50 Montpelier, Oh |

RSS Feed

RSS Feed